Premium Anti-Sticking Coating Paint Product Tire Mould Industrial Boat Paint Easy Application Spray Water Silicone Based Liquid

- Overview

- Recommended Products

Products Description

Place of Origin |

Shandong, China |

Main Raw Material |

PTFE |

Usage |

Appliance Paint, Boat Paint, Metal Paint,Cookware Paint |

Application Method |

Spray |

State |

Liquid Coating |

Brand Name |

Qihang |

Model Number |

Mold coating |

Product Name |

PTFE coating |

Application |

Industry metal paint,Cookware Paint |

Material |

PTFE |

Color |

Customized Colors |

Advantage |

Professional Technical Support |

Type |

Water-based Silicone |

MOQ |

20KG |

Package |

20L |

OEM |

Accepetable |

Products Characteristics

1. Green and environmentally friendly, harmless to human health.

2. Strong adhesion and good toughness, suitable for coating stainless steel, aluminum, phosphated iron, ceramics, and bamboo carbon materials.

3. Excellent high temperature resistance, stable gloss and color under long-term high temperature use.

4. Excellent scratch resistance and anti-corrosion performance, high hardness, non stickiness, and good wear resistance.

5. Excellent sustained non stick ability, able to tolerate cooking materials such as boiling water, salt water, milk, eggs, butter, etc. for a long time.

adhesion |

Level 0 (Hundred Grid Method) |

smell |

nothing |

Thermal Shock |

At 350 ° C/25 ° C, after 20 cycles,

there were no abnormalities in the coating.

|

Cold hardness/hot hardness |

≥ 4H (aluminum alloy, Mitsubishi pencil). |

Wear resistance |

Over 10000 times (with a load of 4.9 kilograms and a 3M scraping cloth) |

Corrosion resistance |

Soak the paint film in acid, 10% NaOH, solvent, water, and saline solution

at 70-80 ° C for 24 hours without any abnormalities.

|

non-stick |

Strong anti pollution properties for soy sauce, pigments, oils, and milk,

meeting the requirements for frying eggs and cooking

rice tests. |

Heat resistance |

> 500 ° C (long-term use temperature), > 700 ° C (short-term use temperature). |

Products Application

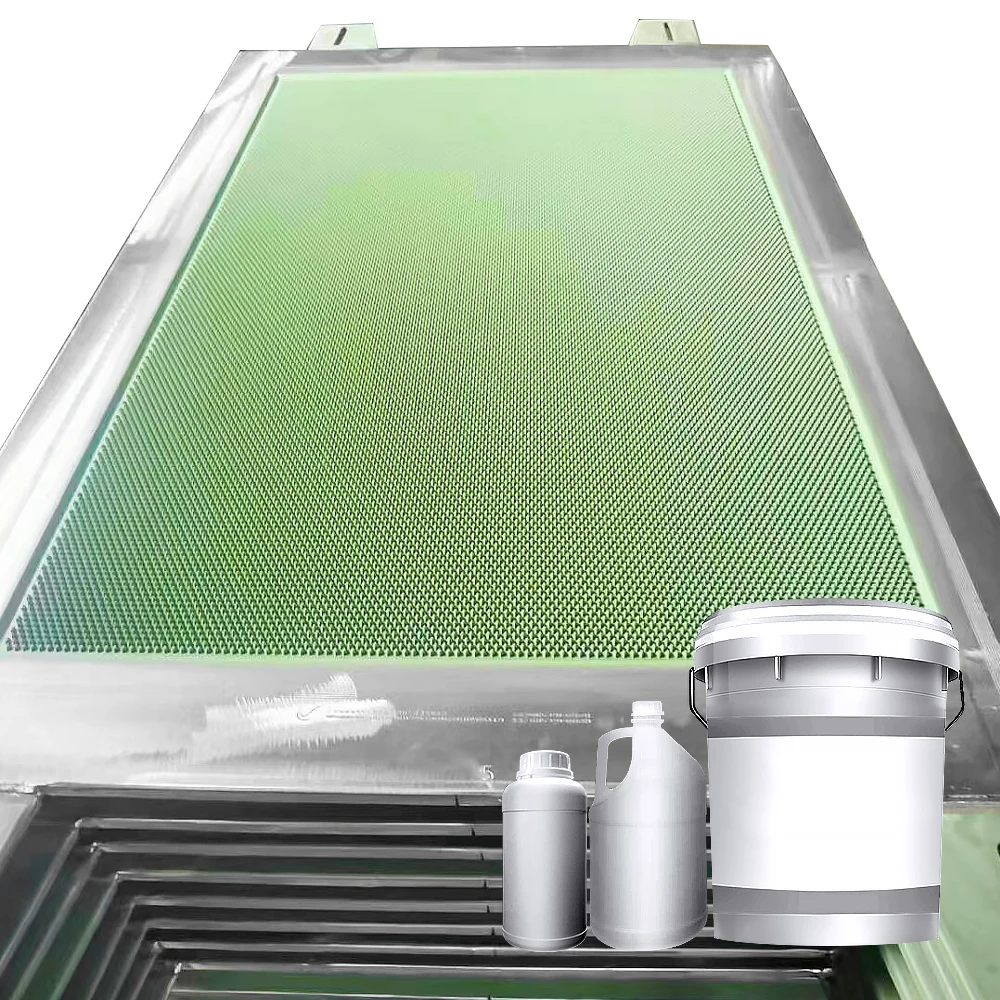

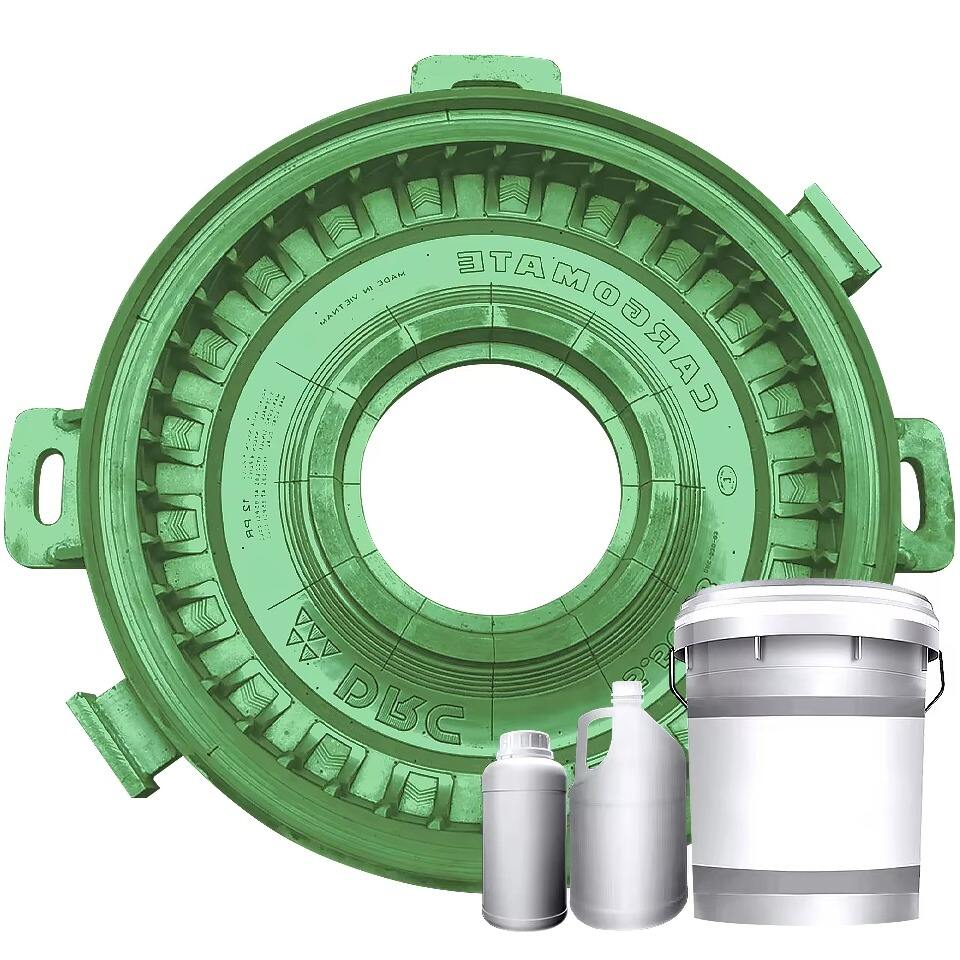

Product Usage Qingdao Qihang Coating Technology Co., Ltd. produces PTFE coatings as high-temperature resistant inorganic non stick coatings, which can be used in ceramics and other industries. They are widely used in metallurgy, petroleum industry, textile industry, electrical products, rubber products industry, and various demolding industries; In industrial fields such as natural gas extraction and aerospace, it can withstand temperatures up to 350 ℃ or even higher. It not only has high temperature resistance, but also has properties such as heat shock resistance and wear resistance. Through coating, the surface of metal and various refractory materials can be modified to improve the performance of the substrate material, save energy, and increase the service life of the metal substrate material by more than 1-2 times. The products developed by our company have been widely used in various mold demolding, anti-corrosion, temperature resistance, wear resistance, high-temperature electric irons, rice cookers, microwave ovens, baking pans and other products. They have excellent adhesion to metals, are very hard, and have more significant strength after high-temperature calcination without cracking. It has good oil resistance, acid and alkali resistance, colorful colors, and is marketed in Southeast Asia, Europe and other countries.

Teflon coating for cookware and kitchenware This product has passed strict testing according to FDA standards and can be applied to various food containers. It is recommended to be used on the inner and outer surfaces of high-end cookware and kitchen utensils, such as frying pans, frying pans, rice cookers, baking pans, etc. The advantages are as follows: Can be used for a long time under high temperature conditions of 200 ℃ -400 ℃; Hardness up to 6-9H: Stable hardness at high temperatures, not easily scratched Wear resistant, hydrophobic and non greasy, antibacterial and anti fouling, easy to clean; Water based environmental protection, non-toxic, harmless, and construction has no adverse effects on human health; Fast heating, low energy consumption, and uniform heating; Low processing temperature can significantly save energy and effectively protect the strength of aluminum and other substrates.

Teflon coating for baking equipment This product can be applied to the outer surface of various open flame or electric heating devices, such as high-end ovens, barbecue utensils, microwave ovens, electric stoves, rice cooker insulation layers, heating furnace heads, hair perm clips, etc. The advantages are as follows: Can be used for a long time under the conditions of 400 ℃ -600 ℃; Hardness 4-6H; Stable at high temperatures, resistant to open flame corrosion, effectively protecting against metal thermal corrosion; Low cost, easy to construct, can partially replace enamel, adheres without peeling off. Fast heating, uniform heating, can reduce the strength decrease, cracks and other problems caused by excessive local heat concentration in some metal products ("anti dry burning")

Teflon coating for electric irons This product is recommended for use on the surface of high-end electric iron soleplates and has the following advantages: Can be used for a long time under the conditions of 200 ℃ -400 ℃, without yellowing and resistant to aging The coating has a high hardness of 6-9H, is wear-resistant, scratch resistant, steam resistant, and has no corrosion or peeling off It has far-infrared heating effect, significantly accelerates temperature rise, saves energy, has an elegant appearance, and can provide multiple colors.

More applications

Used in the food industry The purpose of spraying PTFE is to prevent food from sticking, make baked food easy to demold, have consistent shape, stable quality, shorten downtime, reduce cleaning and maintenance costs, and improve the efficiency of food manufacturing and packaging processes. Our company can spray food grade Teflon on a variety of machinery and equipment related to food manufacturing, such as: dough kneaders for bread and cake processing, rollers, cutters, metal molds, various oven plates, various pans, heat sealing machines, automatic packaging machines for food or granulated sugar, packaging machines for cheese, bacon, sausage, agricultural and aquatic products processing equipment (for example, tea making machines, fish pressing molds, chicken oil frying rods, fish stirring machines, Rice noodles cake making machines, dough making machines, dough molds and bean paste packaging), food and frozen food delivery pipes and food processing machines. There are also various equipment used for sugar refining and brewing.

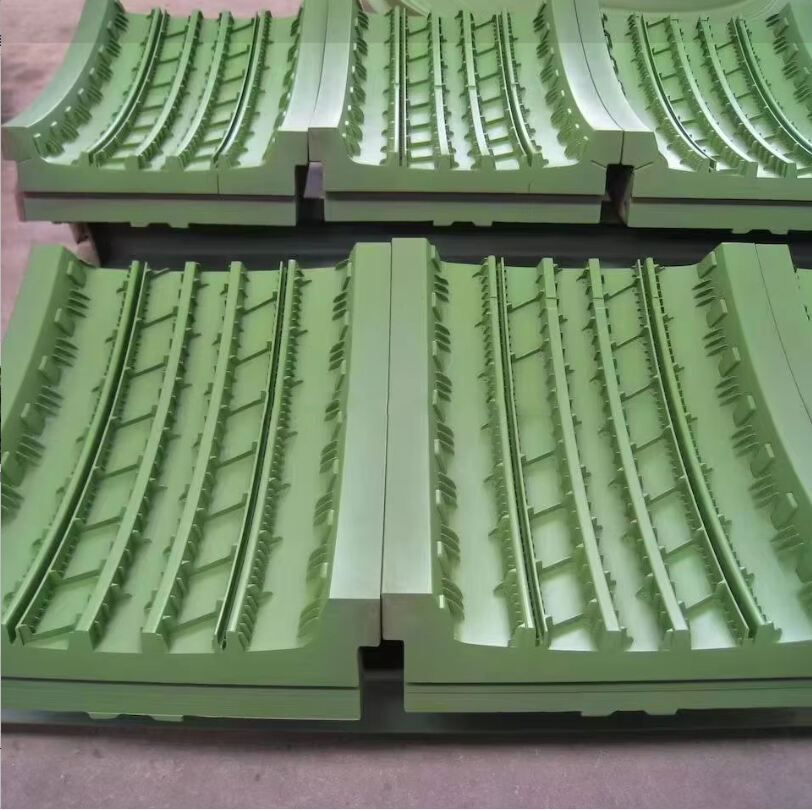

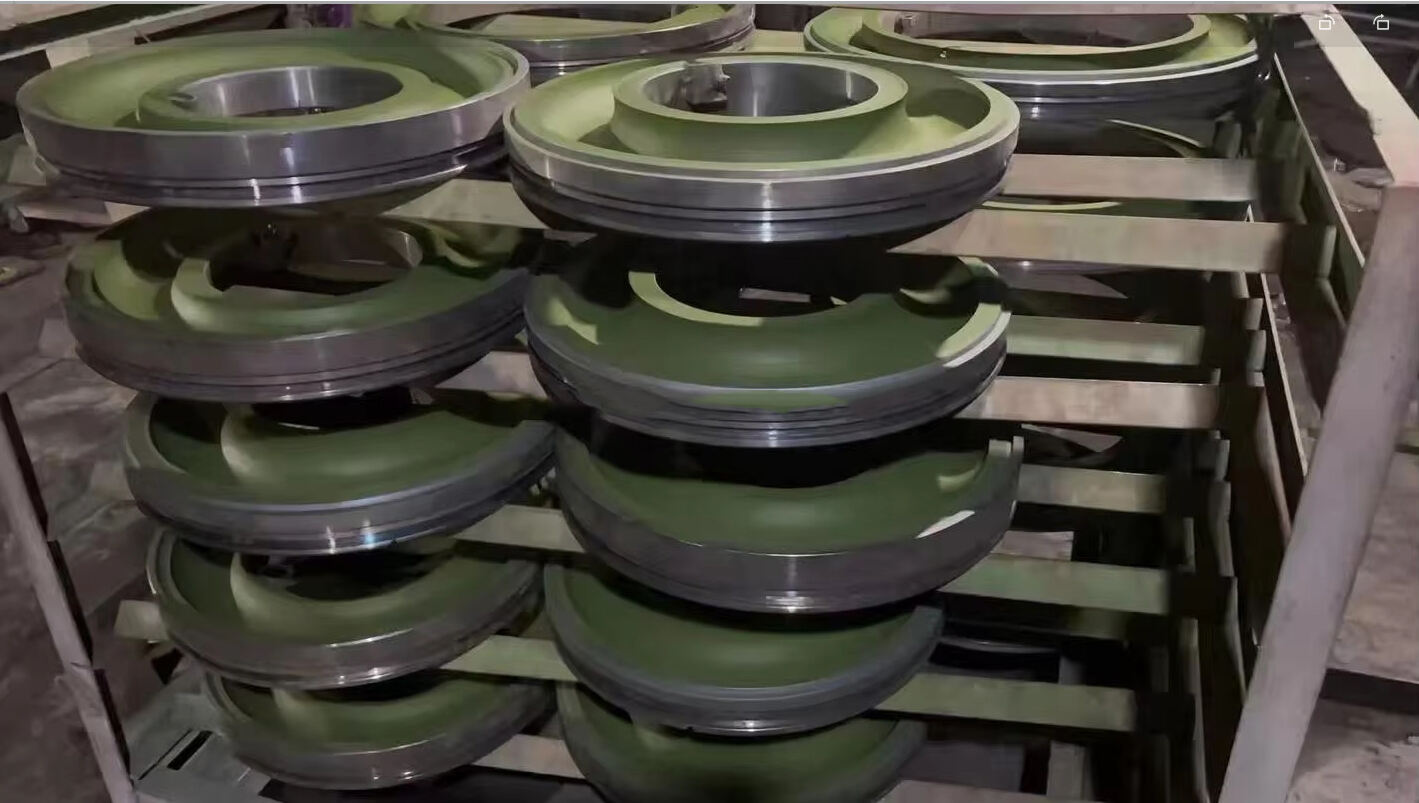

Used in the plastic and rubber industry Based on economic benefits and required functions, our company can choose appropriate PTFE coatings to spray on the surface of the mold for customers to solve the problem of product sticking to the mold and difficult demolding, thereby extending the service life of the mold. For example, molds for manufacturing epoxy resin and phenolic resin products, molds for urethane foam plastic, molds for styrene foam plastic, film production rollers, soles, rubber gloves, tire forming molds, etc., synthetic rubber conveyor belts, manufacturing polyethylene rubber molds, glass low belt rollers, and rollers for manufacturing laminated films.

Used in the electronics and automotive industries The use of PTFE in the electronics and automotive industries is widespread, and the substrate varies in size and material. Our company not only has PTFE coatings, but also resin and ceramic paints, and sprays PTFE in a 100000 level static chamber to meet industrial requirements. For example: mobile phone board, guide valve seat, mixing chamber throttle valve, solenoid valve stem, valve, weatherstripping, carburetor shaft, piston, piston ring, throttle shaft, control rod, hinge pin, various bearings, brake shoes, bearing guard.

Why Choose Us

1、Years of focus The company has been engaged in the non stick coating industry for many years, with a professional R&D team and sales team, which can solve common problems of PTFE for different customers.

1、Years of focus The company has been engaged in the non stick coating industry for many years, with a professional R&D team and sales team, which can solve common problems of PTFE for different customers.2、Excellent quality All products are made of high-quality resin, FDA certified, SGS standard, anti-corrosion and wear-resistant, Scratch resistant and non stick, with high hardness.

3、Widely used Widely used in metallurgy, petroleum industry, textile industry Electrical products, rubber products industry, various demolding industries Business,Industrial sectors such as natural gas extraction and aerospace

4、Perfect service Professional after-sales team, providing you with professional solutions Solution and effective guidance. Timely resolution All problems encountered by customers.

Qingdao Qihang Coating Technology Co., LTD integrates production and research and development, with a professional R&D team and sales team. Since its establishment twenty years ago, it has solved different common problems for different customers, and cooperated with many large well-known rubber, tire, shoe-making, mold, and spray coating enterprises with professional technology and quality. We produce various types of fluorine coatings, Teflon coatings, fluorine powder coatings, non-stick coatings, PAI resin (314, 316 ,204 ,200 ,214 ,7799), Teflon food-grade non-stick coatings,nano-level low-temperature Teflon coatings,c eramic coatings,boron nitride coatings,f luorocarbon paint,special wear-resistant high-temperature resistant coatings,silicone non-stick coatin gs,various electrical functional non-stick co atings,Teflon textile c oatings,special release agents,Teflon water-based paints,h igh-temperature lubricating coa tings,screw coa tings.The paints are divided into high temperature,middle temperature,r oom temperature,w ater-based,oil-based,single-layer,double-layer,triple-l ayer,and various colors.All are made of excellent materials.We sell fluoro fine chemical materials,powders,and liquid PTFE,PFA ETFE ECTFE PAI PES,FDA certification SGS standard!

Production Line

Exhibition

Certifications

Product Packaging

FAQ

Q1:How can I get more information about your product?

A1:You can send us an email or ask our online representatives and we can send you the latest catalog and price list.

Q2:Do you accept OEM or ODM?

A2:Yes,But we have quantity requirements.please contact us directly.

Q3:What is the payment way of your company?

A3:T/T,sight L/C,Paypal,Western Union

Q4:What is the shipping way?

A4:By sea,air,Fedex,DHL,UPS,TNT etc.

Q5:How long for manufacturing once we place order?

A5:It's about 10 days after payment or disposit.